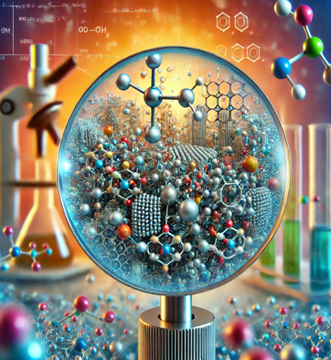

The rapid development of nanotechnology has revolutionized various scientific and industrial fields, including gas sensing. Gas sensors, which are critical for applications ranging from environmental monitoring to industrial safety and medical diagnostics, have greatly benefited from the unique properties of nanomaterials. These materials, with their high surface area-to-volume ratio and tunable properties, have ushered in a new era of high-performance and highly selective gas sensors.

The Need for Advanced Gas Sensors

Traditional gas sensing technologies, while effective, often suffer from limitations such as low sensitivity, slow response times, and susceptibility to environmental conditions. As industries demand more precise and reliable monitoring systems, there has been a significant push towards developing sensors capable of detecting trace amounts of gases under varying conditions.

Nanomaterials: A Game-Changer

Nanomaterials have emerged as the cornerstone for the next generation of gas sensors. Their nanoscale dimensions allow for enhanced interaction with gas molecules, leading to improved sensitivity and selectivity. Some of the most prominent nanomaterials used in gas sensing include:

- Metal Oxide Nanostructures

Metal oxides like ZnO, SnO2, and TiO2 are among the most studied materials for gas sensing. Their ability to change electrical resistance in the presence of specific gases makes them ideal for detecting a wide range of gases, including NO2, CO, and H2. Recent advancements have focused on engineering their morphology—nanowires, nanorods, and nanoparticles—to optimize gas adsorption and electron transport.

- Carbon-Based Nanomaterials

Materials like graphene, carbon nanotubes (CNTs), and graphene oxide have gained attention due to their exceptional electrical conductivity and chemical stability. Their two-dimensional structure provides an extensive surface area for gas interaction. Graphene, for instance, has shown remarkable performance in detecting low concentrations of toxic gases like NH3 and CO2.

- Hybrid Nanomaterials

Combining different nanomaterials often results in synergistic properties that surpass those of the individual components. For example, incorporating noble metal nanoparticles (e.g., Au, Ag, Pt) into metal oxides or carbon-based materials can enhance their sensitivity and selectivity by creating active catalytic sites.

- Organic-Inorganic Nanocomposites

These materials leverage the flexibility and functionality of organic polymers with the robustness of inorganic nanomaterials. They are particularly useful in wearable and flexible gas sensors for applications such as personal health monitoring.

Key Innovations in Gas Sensing

Recent advancements in nanomaterials have led to breakthroughs in gas sensing technologies:

- Room Temperature Sensing: Traditional sensors often require high operating temperatures to achieve desired sensitivity. Nanomaterials enable room-temperature gas sensing, significantly reducing power consumption and broadening their applicability.

- Selective Detection: By functionalizing nanomaterials with specific chemical groups or catalysts, researchers have achieved highly selective detection of target gases in complex environments.

- Miniaturization: Nanotechnology facilitates the development of compact and portable gas sensors that can be integrated into handheld devices and IoT systems.

- Real-Time Monitoring: Advances in electronic integration and data processing allow for real-time gas detection and analysis, which is crucial for industrial and environmental applications.

Challenges and Future Directions

Despite the tremendous potential of nanomaterials, several challenges remain:

- Stability: Many nanomaterials degrade or lose sensitivity over time, especially in harsh environments. Research into durable materials and protective coatings is ongoing.

- Scalability: While lab-scale production of nanomaterials is feasible, scaling up to industrial levels remains a hurdle due to high costs and complex fabrication processes.

- Interference: Overcoming cross-sensitivity to other gases and environmental factors is crucial for practical applications.

Looking ahead, the integration of artificial intelligence (AI) and machine learning with nanomaterial-based gas sensors could further enhance their performance. AI can analyze complex sensor data to improve accuracy and predict gas concentrations with high precision. Additionally, interdisciplinary collaborations between material scientists, chemists, and engineers will be essential for pushing the boundaries of this exciting field.

Conclusion

Nanomaterials have undoubtedly transformed the landscape of gas sensing, enabling the development of sensors that are more sensitive, selective, and versatile than ever before. As research continues to address current challenges, the future holds immense promise for these materials to play a pivotal role in ensuring environmental safety, industrial efficiency, and public health.